Khetha ku: Iimveliso zebhokisi yegiya ephindwe kabini zimanzi, iqokobhe elixhasayo liqukethe iqokobhe le-clutch kunye nebhokisi yegiya, amaqokobhe amabini aveliswa yindlela yoxinzelelo oluphezulu, kwinkqubo yophuhliso lwemveliso kunye nemveliso ifumene inkqubo enzima yokuphucula umgangatho. , blank comprehensive qualified rate malunga ne-60% 95% ekupheleni kokunyuka ukuya kumanqanaba angama-2020, Eli nqaku lishwankathela izisombululo kwiingxaki zomgangatho oqhelekileyo.

Ukuhanjiswa kwe-clutch emanzi kabini, esebenzisa iseti yegiya ye-cascade entsha, inkqubo ye-electro-mechanical shift drive kunye ne-electro-hydraulic clutch actuator entsha. Iqokobhe elingenanto lenziwe ngoxinzelelo oluphezulu lokuphosa i-aluminium alloy, eneempawu zobunzima bokukhanya kunye namandla aphezulu. Kukho impompo ye-hydraulic, ulwelo lokuthambisa, umbhobho wokupholisa kunye nenkqubo yokupholisa yangaphandle kwibhokisi yegiya, ebeka phambili iimfuno eziphezulu ekusebenzeni koomatshini kunye nokusebenza kokutywinwa kweqokobhe. Eli phepha lichaza indlela yokusombulula iingxaki ezisemgangathweni ezifana nokuguquguquka kweqokobhe, umngxuma wokushwabana komoya kunye nezinga lokuphumelela elivuzayo nelichaphazela izinga lokuphumelela kakhulu.

1,Isisombululo sengxaki ye-deformation

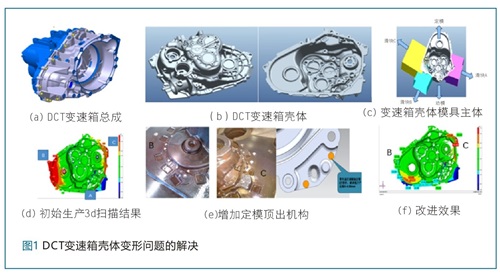

Umzobo 1 (a) ngezantsi,Ibhokisi yegiya yenziwe nge-high-pressure cast aluminiyam yealloy gearbox yendlu kunye nendlu ye-clutch. Izinto ezisetyenziswayo yi-ADC12, kwaye ubukhulu bayo bodonga olusisiseko bumalunga ne-3.5mm. Iqokobhe lebhokisi yegiya libonisiwe kuMfanekiso 1 (b). Ubungakanani obusisiseko buyi-485mm (ubude) × 370mm (ububanzi) × 212mm (ubude), umthamo ngu-2481.5mm3, indawo eqikelelweyo yi-134903mm2, kunye nobunzima obunetha malunga ne-6.7kg. Yindawo enomngxuma onzulu obhityileyo. Ukuqwalasela iteknoloji yokuvelisa kunye nokucubungula i-mold, ukuthembeka kokubumba imveliso kunye nenkqubo yokuvelisa, i-mold ihlelwe njengoko kubonisiwe kwi-Figure 1 (c), eyakhiwe ngamaqela amathathu e-sliders, i-mold ehambayo (kwindlela yangaphandle). i-cavity) kunye nesikhunta esisisigxina (kwicala le-cavity yangaphakathi), kunye nesantya sokunciphisa i-thermal ye-casting yenzelwe ukuba yi-1.0055%.

Ngokwenyani, kwinkqubo yovavanyo lokuqala lokuphosa ukufa, kwafunyaniswa ukuba ubungakanani bendawo yemveliso eveliswe ngokuphosa ukufa bahluke kakhulu kwiimfuno zoyilo (ezinye izikhundla zazingaphezulu kwe-30% isaphulelo), kodwa ubungakanani bokubumba bufanelekile kwaye izinga lokucutheka xa lithelekiswa nobona bungakanani nalo lalihambelana nomthetho wokushwabana. Ukuze ufumane unobangela wengxaki, ukuskena kwe-3D kwegobolondo lomzimba kunye nethiyori ye-3D isetyenziselwe ukuthelekisa nokuhlalutya, njengoko kubonisiwe kuMfanekiso 1 (d). Kwafunyaniswa ukuba indawo yokubeka isiseko sendawo engenanto yayikhubazekile, kwaye inani le-deformation laliyi-2.39mm kwindawo B kunye ne-0.74mm kwindawo C. Ngenxa yokuba imveliso isekelwe kwindawo ye-convex ye-A, B, C elandelayo. processing positioning benchmark kunye ne-benchmark yokulinganisa, le deformation ikhokelela kumlinganiselo, enye ingqikelelo yobungakanani ukuya ku-A, B, C njengesiseko senqwelomoya, indawo yomngxuma ngaphandle komyalelo.

Uhlalutyo lwezizathu zale ngxaki:

① Umgaqo-siseko woyilo loxinzelelo oluphezulu yenye yeemveliso emva kokudilizwa, ukunika imilo kwimveliso kwimodeli eguquguqukayo, efuna impembelelo kwimodeli eguquguqukayo yamandla epakethe inkulu kunemikhosi esebenza kwingxowa yokubumba eqinileyo, ngenxa umngxuma onzulu iimveliso ezizodwa ngaxeshanye, umngxuma enzulu ngaphakathi cores kwi ukungunda elimisiweyo kunye nomngxuma ngaphandle umngxuma eyenziwe umphezulu oshukumayo iimveliso ukungunda ukwenza isigqibo icala isahlulelo ngundo xa ngokuqinisekileyo uya kubandezeleka ukutsalwa;

②Kukho izilayidi kwicala lasekhohlo, elisezantsi nasekunene lokungunda, ezidlala indima encedisayo ekubambeni phambi kokuba udilizwe. Amandla amancinci axhasayo akwi-B ephezulu, kwaye ukuthambekela okupheleleyo kuku-concave kwi-cavity ngexesha lokuncipha kwe-thermal. Ezi zizathu zimbini zingentla zikhokelela kolona tshintsho lukhulu ku-B, lulandelwa nguC.

Iskimu sokuphucula ukusombulula le ngxaki kukongeza i-fixed die ejection mechanism Figure 1 (e) kwindawo ehleliweyo yokufa. Kwi-B inyuke i-6 iseti yokubumba i-plunger, yongeza i-plunger yokungunda esisigxina kwi-C, intonga ye-pin esisigxina kukuxhomekeka kwincopho yokusetha kwakhona, xa uhambisa i-mold clamping plane usete i-lever reset uyicinezele kwi-mold, i-mold automatic i-die pressure iyanyamalala, umva ipleyiti entwasahlobo kwaye emva koko utyhale incopho ephezulu, thatha inyathelo lokuqala lokukhuthaza iimveliso ziphuma kubumba obusisigxina, ukuze kuqatshelwe ukuguqulwa komonakalo owenziweyo.

Emva kokuguqulwa kokubumba, i-deformation deformation iyancipha ngempumelelo. Njengoko kuboniswe kwi-FIG.1 (f), i-deformations kwi-B kunye ne-C ilawulwa ngokufanelekileyo. I-Point B yi-0.22mm kunye ne-point C yi-0.12, ehlangabezana nemfuneko ye-contour engenanto ye-0.7mm kwaye ifezekise imveliso yobuninzi.

2, Isisombululo somngxunya wokushwabana kweqokobhe kunye nokuvuza

Njengoko kwaziwa kubo bonke, ukuphoswa koxinzelelo oluphezulu kuyindlela yokwenza apho isinyithi solwelo sizaliswe ngokukhawuleza kwisigxina sokubumba isinyithi ngokufaka uxinzelelo oluthile kwaye luqina ngokukhawuleza phantsi koxinzelelo lokufumana ukuphosa. Nangona kunjalo, ngokuxhomekeke kwiimpawu zoyilo lwemveliso kunye nenkqubo yokuphosa ukufa, kusekho iindawo ezithile zamalungu ashushu okanye imingxunya yokunciphisa umoya kwimveliso, ebangelwa:

(1) Ukuphoswa koxinzelelo kusebenzisa uxinzelelo oluphezulu ukucinezela isinyithi elulwelo kumgodi wokungunda ngesantya esiphezulu. Igesi ekwigumbi loxinzelelo okanye i-mold cavity ayikwazi ukukhutshwa ngokupheleleyo. Ezi gesi zibandakanyeka kwintsimbi engamanzi kwaye ekugqibeleni zikhona ekugalweni ngendlela yeepores.

(2) Ukunyibilika kwerhasi kwi-aluminiyam engamanzi kunye ne-alloy eqinileyo ye-aluminiyam yahlukile. Kwinkqubo yokuqinisa, irhasi iyancipha ngokungenakuthintelwa.

(3) Isinyithi solwelo siqina ngokukhawuleza kwi-cavity, kwaye kwimeko yokungaphangi okusebenzayo, ezinye iindawo zokuphosa ziya kuvelisa i-shrinkage cavity okanye i-shrinkage porosity.

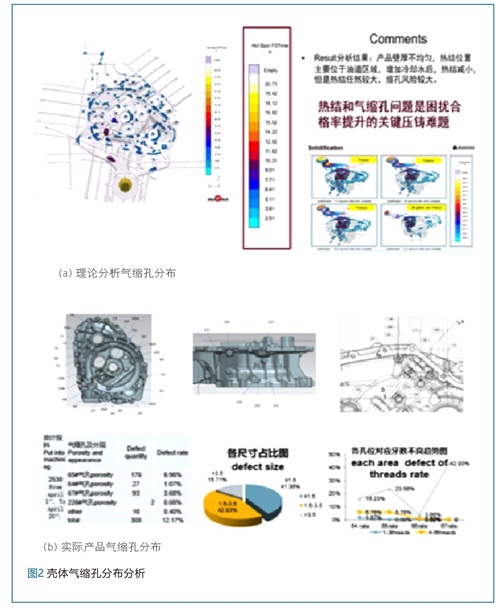

Thatha iimveliso ze-DPT eziye zangena ngokulandelelana kwisampulu yezixhobo kunye nesigaba sokuvelisa ibhetshi encinci njengomzekelo (jonga umfanekiso 2) : Isantya sesiphako somngxuma wokuqala wokunciphisa umoya wemveliso kubalwa, kwaye iphezulu yayiyi-12.17%, phakathi kwayo umoya. umngxuma wokushwabana mkhulu kune-3.5mm kubalelwa kwi-15.71% yeziphene zizonke, kwaye umngxuma wokuncipha womoya ophakathi kwe-1.5-3.5mm ubalelwa kuma-42.93%. Le mingxunya yokunciphisa umoya yayigxininiswe kwimingxuma ethile enemisonto kunye neendawo zokutywina. Ezi ziphene ziyakuchaphazela amandla okudibanisa i-bolt, ukuqina komphezulu kunye nezinye iimfuno zokusebenza kwe-scrap.

Ukusombulula ezi ngxaki, iindlela eziphambili zezi zilandelayo:

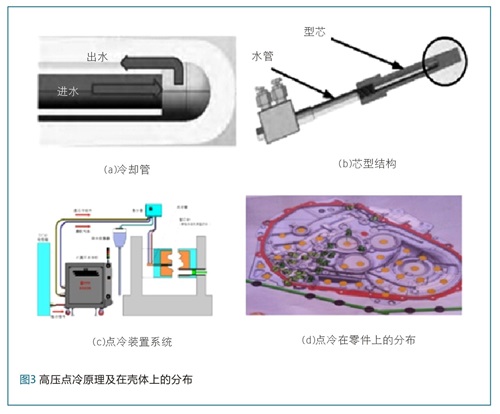

2.1INKQUBO YOKUPHOLISA ibala

Ifanele iindawo zomngxunya onzulu kunye namalungu amakhulu angundoqo. Inxalenye yokwakheka kwezi zakhiwo inemingxuma embalwa enzulu okanye indawo enzulu yomgodi wokutsalwa, njl. njl., kwaye iimolds ezimbalwa zisongelwe sisixa esikhulu se-aluminium engamanzi, ekulula ukubangela ukufudumeza komngundo, kubangele ukuncamathelisa. ubunzima bokungunda, ukuqhekeka okushushu kunye nezinye iziphene. Ngoko ke, kuyimfuneko ukunyanzela ukupholisa amanzi okupholisa kwindawo yokudlula ye-mold mold enzulu. Inxalenye yangaphakathi yondoqo kunye nobubanzi obungaphezulu kwe-4mm ipholiswe ngu-1.0-1.5mpa amanzi aphezulu, ukwenzela ukuba kuqinisekiswe ukuba amanzi okupholisa abandayo kwaye ashushu, kwaye izicubu ezijikelezileyo ze-core zingaqala ukuqinisa kwaye zenze i umaleko oshinyeneyo, ukuze kuncitshiswe ukuncipha kunye nokuthambekela kwe-porosity.

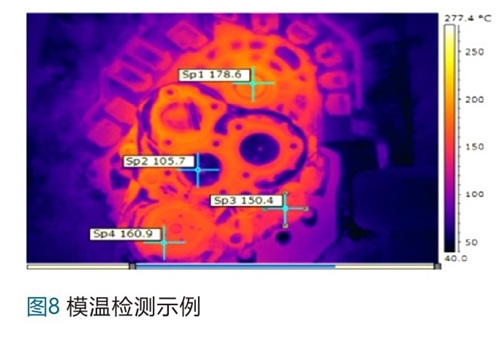

Njengoko kuboniswe kwi-Figure 3, idibaniswe nedatha yokuhlalutya kwezibalo zokulinganisa kunye neemveliso zangempela, indawo yokugqibela yokupholisa indawo yokupholisa iphuculwe, kwaye indawo yokupholisa yoxinzelelo oluphezulu njengoko kuboniswe kwi-Figure 3 (d) ibekwe kwi-mold, elawulwa ngokufanelekileyo. ubushushu bemveliso kwindawo edibeneyo eshushu, yaqonda ukuqiniswa okulandelelanayo kweemveliso, yanciphisa ngokufanelekileyo ukuveliswa kwemingxuma yokuncipha, kwaye yaqinisekisa izinga elifanelekileyo.

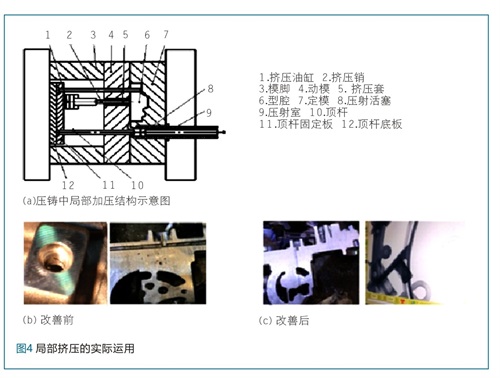

2.2I-extrusion yendawo

Ukuba ubukhulu bodonga loyilo lwesakhiwo semveliso abulingani okanye kukho iindawo ezinkulu ezishushu kwiindawo ezithile, imingxuma yokunciphisa iyancipha ukubonakala kwinxalenye yokugqibela eqinisiweyo, njengoko kuboniswe kwi-FIG. 4 (C) ngezantsi. Imingxuma yokucutheka kwezi mveliso ayinakuthintelwa yinkqubo yokuphosa ukufa kunye nokwandisa indlela yokupholisa. Ngeli xesha, i-extrusion yendawo ingasetyenziselwa ukusombulula ingxaki. Umzobo wesakhiwo soxinzelelo oluyinxenye njengoko kubonisiwe kumfanekiso wesi-4 (a), oko kukuthi, ifakelwe ngokuthe ngqo kwisilinda sokungunda, emva kokuba isinyithi esinyibilikisiweyo sigcwaliswa kukungunda kwaye saqina ngaphambili, hayi ngokupheleleyo kulwelo lwentsimbi oluqilima semi-oluqilima kumngxuma, ekugqibeleni ukuqina kodonga olungqindilili ngoxinzelelo lwentonga ye-extrusion inyanzeliswa ukutyisa ukunciphisa okanye ukuphelisa iziphene zayo zomngxunya wokushwabana, ukuze kufumaneke umgangatho ophezulu wokuphosa ukufa.

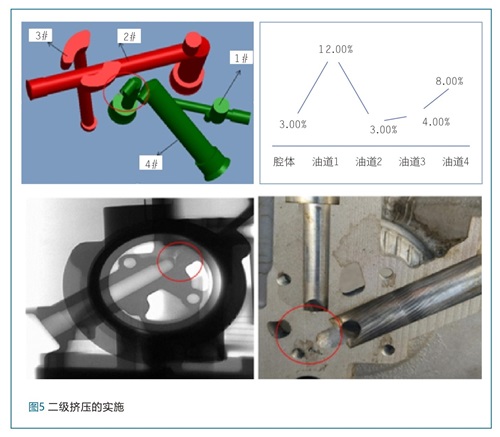

2.3I-extrusion yesibini

Inqanaba lesibini le-extrusion kukuseta i-cylinder ye-stroke kabini. I-stroke yokuqala igqibezela ukubumba inxenye yomngxuma wokuqala wangaphambili, kwaye xa i-aluminiyam engamanzi ejikeleze undoqo iqiniswa ngokuthe ngcembe, inyathelo lesibini le-extrusion liqalisiwe, kwaye isiphumo esiphindiweyo sokuphosa kwangaphambili kunye ne-extrusion ekugqibeleni sifezekiswe. Thatha i-gearbox yezindlu njengomzekelo, izinga elifanelekileyo lovavanyo oluqinileyo lwegesi lwendlu yebhokisi yegiya kwinqanaba lokuqala leprojekthi lingaphantsi kwama-70%. Ukuhanjiswa kwamacandelo okuvuza ikakhulu kukuhlangana kwe-oyile ye-1 # kunye ne-oyile ye-4 # (isangqa esibomvu kuMfanekiso 5) njengoko kubonisiwe ngezantsi.

2.4UKULAHLA INKQUBO YEMBAleki

Inkqubo yokugalela yentsimbi die ukuphosa ngundo ngumjelo ogcwalisa umngxuma imodeli die casting kunye nolwelo metal otyhidiweyo kwigumbi lokushicilela of kufa umatshini yokuphosa phantsi kwemeko ubushushu obuphezulu, uxinzelelo oluphezulu kunye nesantya esiphezulu. Ibandakanya imbaleki ethe tye, imbaleki enqamlezileyo, imbaleki yangaphakathi kunye nenkqubo yokukhupha i-overflow exhaust. Bakhokelwa kwinkqubo yokuzalisa i-cavity yesinyithi, i-flow state, isantya kunye noxinzelelo lokutshintshwa kwetsimbi ye-liquid, umphumo wokukhupha kunye ne-die mold idlala indima ebalulekileyo kwimiba efana ne-thermal equilibrium state yolawulo kunye nommiselo, ngoko ke. , inkqubo yokungena kugqitywe ukuba kufa umgangatho wokuphosa umphezulu kunye nomba obalulekileyo wemeko yangaphakathi ye-microstructure. Uyilo kunye nokugqitywa kwenkqubo yokugalela kufuneka isekelwe kwindibaniselwano yethiyori kunye nokusebenza.

2.5PirowusiOukuzaliseka

Inkqubo yokuphosa i-Die yinkqubo yokucubungula eshushu edibanisa kwaye isebenzise umatshini wokuphosa ukufa, i-die casting die kunye nentsimbi engamanzi ngokwenkqubo yenkqubo ekhethiweyo kwangaphambili kunye nemilinganiselo yenkqubo, kwaye ifumana ukuphosa ukufa ngoncedo lokuqhuba amandla. Kuthatha zonke iintlobo zezinto eziqwalaselwayo, ezinje ngoxinzelelo (kubandakanywa amandla okutofa, ukutofa okukodwa koxinzelelo, amandla okwandisa, amandla okutshixa umngundo), isantya sokutofa (kubandakanya isantya sepunch, isantya sangaphakathi sesango, njl.njl.), Ukuzalisa isantya, njl. , amaqondo okushisa ahlukeneyo (iqondo lokushisa elinyibilikayo lesinyithi, iqondo lokushisa lokufa, iqondo lokushisa lokubumba, njl.), amaxesha ahlukeneyo (ixesha lokuzalisa, ixesha lokubamba uxinzelelo, ixesha lokugcinwa kwesikhunta, njl. njl.), iipropati ezishisayo zokubumba (izinga lokutshintshwa kobushushu, ukushisa izinga lomthamo, i-gradient yeqondo lokushisa, njl.)

2.6Ukusetyenziswa kweendlela ezintsha

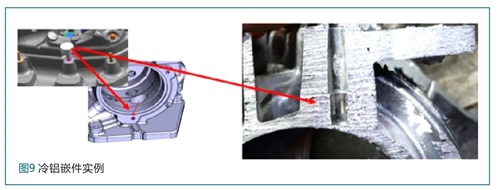

Ukuze kusonjululwe ingxaki yokuvuza kwamalungu akhululekileyo ngaphakathi kumacandelo athile eqokobhe lebhokisi yegiya, isisombululo sebhloko ye-aluminium ebandayo sasetyenziswa ubuvulindlela emva kokuqinisekiswa ngawo omabini amacala okubonelela kunye nemfuno. Okokuthi, ibhloko ye-aluminium ilayishwe ngaphakathi kwemveliso ngaphambi kokuzaliswa, njengoko kuboniswe kuMzobo 9. Emva kokuzaliswa kunye nokuqina, le nto ifakela ihlala ngaphakathi kwiqumrhu lecandelo ukuxazulula ingxaki ye-shrinkage yendawo kunye ne-porosity.

Ixesha lokuposa: Sep-08-2022