Uxinzelelo oluphezulu lwe-die casting yindlela eyenza ulwelo okanye i-semi-liquid metal igcwalise i-cavity ye-die casting mold ngesantya esiphezulu kunye noxinzelelo oluphezulu, kunye neefom kunye nokuqinisa phantsi koxinzelelo lokufumana ukuphosa.

1.Inkqubo yokuphosa uxinzelelo oluphezulu

1.1

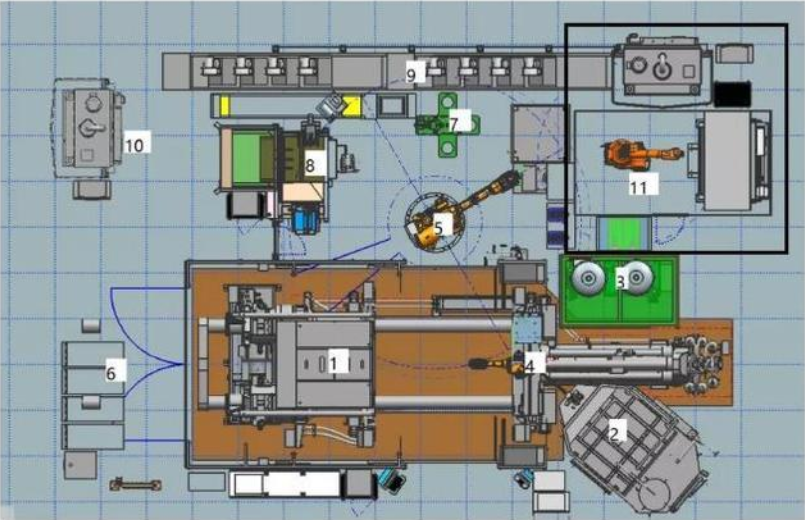

Okwangoku, isiqithi se-die-casting ngokubanzi siya kuqwalasela uqwalaselo olulandelayo; Umatshini wokufa kunye ne-vacuum, i-furnace yokugcina ubushushu ixhotyiswe ngenkqubo yokuphosa yobungakanani, imveliso enohlobo lwenkqubo yokutshiza, ukunciphisa ixesha lokutshiza, irobhothi ukuthatha iinxalenye, ibhegi ye-slag, ukusika ikhowudi kunye nomnye umsebenzi, ukusika kokugqibela inkqubo yesango; Isiqithi se-die-casting sinokuphuculwa ukucoca ngokuzenzekelayo phantsi kweemeko eziphezulu zomthamo.

1.2

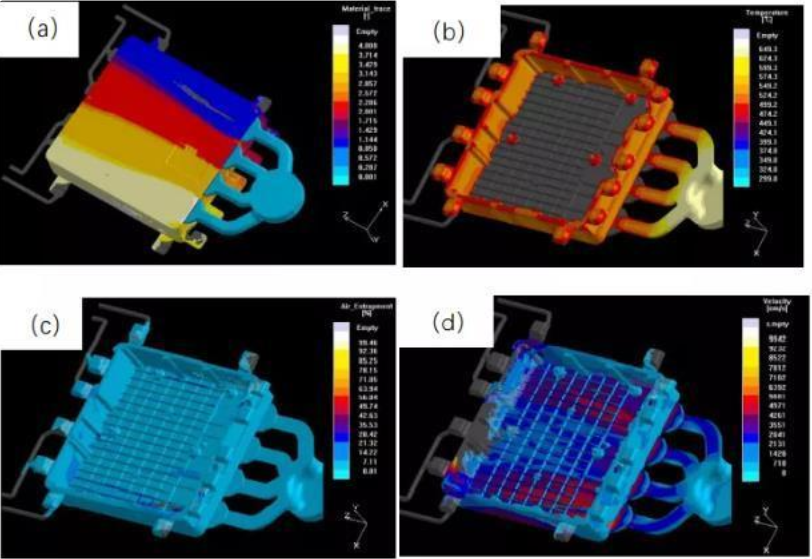

Uhlalutyo lwe-CAE lusetyenziswa ngokubanzi kwi-industry casting industry, emelwe yi-PROCAST, MAGMA, flow-3D, njl. Ngokweziphumo zokubala zokuzalisa ukuhamba kunye nokuhanjiswa kwesantya, ukulinganisa kunokuqikelela ngokuchanekileyo iziphene ezifana nokubhalisa, ukubandakanywa kunye ukuzaliswa kakubi, okuphucula kakhulu isivuno kunye nokugcina ixabiso elinenjongo kakhulu. Sisixhobo esiluncedo kakhulu ukuyila ngokukhawuleza nangesayensi yonke inkqubo yokuphosa (isango, i-sprue kunye netanki yokuphuphuma, njl.njl.) yokuphosa ukufa. Lungiselela iiparamitha zenkqubo yokuphosa, ukunciphisa inani lovavanyo lokubumba, ukunciphisa iindleko zokuphosa, ukuphucula umgangatho wemveliso. Isoftware ye-CAE yayisetyenziselwa uhlalutyo oluqhelekileyo lokuzaliswa, ukuqina, ukuhanjiswa kwe-porosity kunye neengxelo zokusasazwa kwesantya

1.3 Ukusetyenziswa kwevacuum die casting

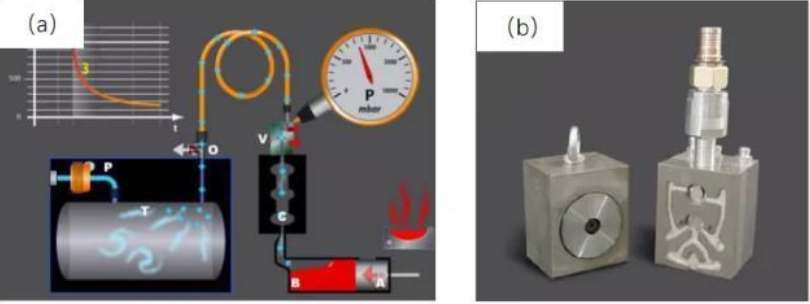

Ngokubonelelwa ngokuqhubekayo kweemfuno zomgangatho wemveliso, ukusetyenziswa kwe-vacuum yokucombulula ingxaki yokuzaliswa kunye nokuqina komoya we-castings kuye kwaphuhliswa kakuhle, kwaye i-vacuum valve isetyenziswa ngokuqhelekileyo, i-vacuum valve esetyenziswa ngokuqhelekileyo inezi zakhiwo ezimbini ezilandelayo. Umzobo 3 ngumzobo weskimu wevalve yokufunxa. Njengenkqubo eqhelekileyo yokuphosa ukufa, emva kokuba amanzi e-aluminium engena kwigumbi, ukucoca kuqala ukuqalisa. Emva koko, xa umatshini wokuphosa ukufa uqala ngesantya esiphezulu, amandla e-kinetic wamanzi e-aluminium kuxhomekeke ekuchukumiseni ipleyiti yasentwasahlobo yevalve yokufunxa. Xa usebenzisa i-valve ye-vacuum yomatshini, ivalwe ngokubanzi xa ufudumeza i-mold. Xa i-preheating igqityiwe, i-valve ye-vacuum ingasetyenziselwa kuphela xa isantya esiphezulu kunye noxinzelelo luqalisiwe. I-valve ye-vacuum yomatshini ineenzuzo zokusetyenziswa okulula, kodwa ukuchaneka kokulungiswa kwevalve yevacuum iphezulu, kwaye ixabiso le-vacuum valve liphezulu kakhulu. Umzobo 4 ngumzobo weskim sevalve yevacuum yehydraulic. Umgaqo wevacuum yomatshini uyafana. Xa i-punch iqala, i-vacuum iqala, kodwa umgaqo wokuvala i-vacuum valve uhlukile. Xa i-valve ye-vacuum ye-hydraulic iqalwa ngokubanzi ngesantya esiphezulu, uhlobo luthunyelwa kwi-hydraulic system ye-vacuum valve ngexesha elifanayo, kwaye i-vacuum valve ivaliwe. Iindleko zevalve yokucoca i-hydraulic vacuum iphantsi, kodwa ifuna ukuba iiparamitha zenkqubo yokuphosa ukufa kunye noyilo lokungunda kufuneka luhambelane, ngaphandle koko ukuphoswa kwamanzi e-aluminium kwivalve yokucoca kuya kubangela ukuvaleka.

2.Ukusaswa

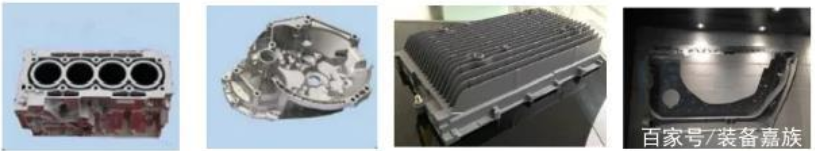

Okwangoku, iimveliso zokuphosa i-aluminium ialloy die zahlulwe zibe ziindidi ezintathu ngokwemali. Inqanaba lokuqala limoto, isithuthuthu, iqokobhe lokuhambisa injini elimelwe yi-injini ye-injini, i-cylinder body njalo njalo. Uhlobo lwesibini liqokobhe lesikhululo sesiseko kunye neqokobhe lokucoca elimelwe lunxibelelwano lwenethiwekhi, kwaye uhlobo lwesithathu lulwakhiwo lomzimba olunemfuno ephezulu yokusebenza koomatshini. Njengoko kubonisiwe emfanekisweni, yimveliso ye-aluminiyam eqhelekileyo yokuphosa:

3.Isiphelo

I-alloy ye-aluminium inamandla athile aphezulu kunye nokuchasana kakuhle kwe-corrosion, ukuhanjiswa kombane okugqwesileyo. Ngaphantsi kwemekobume yentlalo yokugcinwa kwamandla kunye nokunciphisa ukukhutshwa kunye nokukhuselwa kokusingqongileyo okuluhlaza, i-aluminium alloy die casting iphuhliswe ngokukhawuleza e-China. Ndiyakholelwa ukuba kwixesha elizayo, iimveliso ze-aluminium alloy ziya kuba zihlukeneyo. I-deformation ephambili ikule miba ilandelayo; I-1) Ngokuphuhliswa kweemveliso, kuya kuqhuba ukuphuhliswa kwezinto ezintsha ze-aluminium alloy alloy, ezifana ne-: conductivity ephezulu ye-thermal, amandla aphezulu kunye nokuqina okuphezulu; 2) izinto ezintsha zokuphosa i-aluminium ialluminiyam nazo ziya kuqhuba uphuhliso lwetekhnoloji entsha yokuphosa ukufa, njengenkqubo yokuphosa i-semi-solid, i-vacuum ephezulu yokuphosa i-3) uphuhliso lwetekhnoloji luya kunika izixhobo, izixhobo ezincedisayo ezibeka phambili iimfuno eziphezulu. , njenge: ukuphosa ukufa okukhulu, umatshini wokushisa wokufa, izixhobo zokutshiza, ukukhulula umatshini ohambelanayo, umatshini wokutshayela, umatshini obandayo, ulawulo lobushushu lokubumba kunye nenkqubo yokufumanisa, njl.

Ixesha lokuposa: May-19-2022